Food and beverage industry checklist and inspection software

Run inspections and optimize processes to meet the industry highest

quality standards. Empower your workers,

detect and report improvement opportunities, standardize

operations and share reports to create an efficient and more

secure environment in food production. Analyze different

KPIs in the business intelligence section to monitor

operations remotely at any time.

How can be Full Audits implemented in the Food and beverage industry?

- Monitor workers performance and buildings environment, health and safety standards.

- Control truck operations, loading/unloading area and products transportation.

- Monitor hygiene and safety of the plant and employees.

- Execute quality, production, machinery, transportation and documentation inspections daily.

- Control and prevent pests.

- Check and maintain the condition of industrial equipement, trucks, transportation and tools.

What are the advantages of implementing Full Audits in the food and beverage industry?

Al utilizar nuestro software puedes:

- Consolidate your information, migrate from paper to digital .

- Work in remote locations, without internet connection.

- Automatic information consolidation in Dashboards.

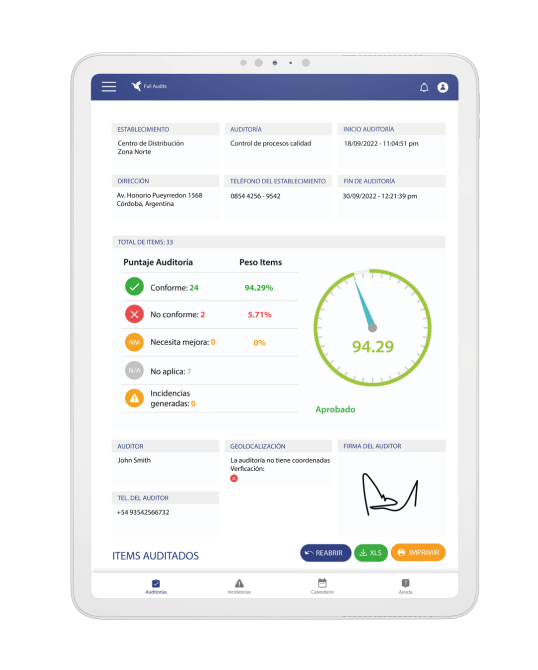

- Audits report created automatically.

- %50 of time reduction during the auditing process.

- Involve all teams within your organization on the quality management process.

- Direct access to your data through the web application.

- Identify improvement opportunities easily.

- Work to accomplish following quality standards:

We are here to help you

Run inspections with automated tools, evolving and avoiding manual processes with our cross-platform software.

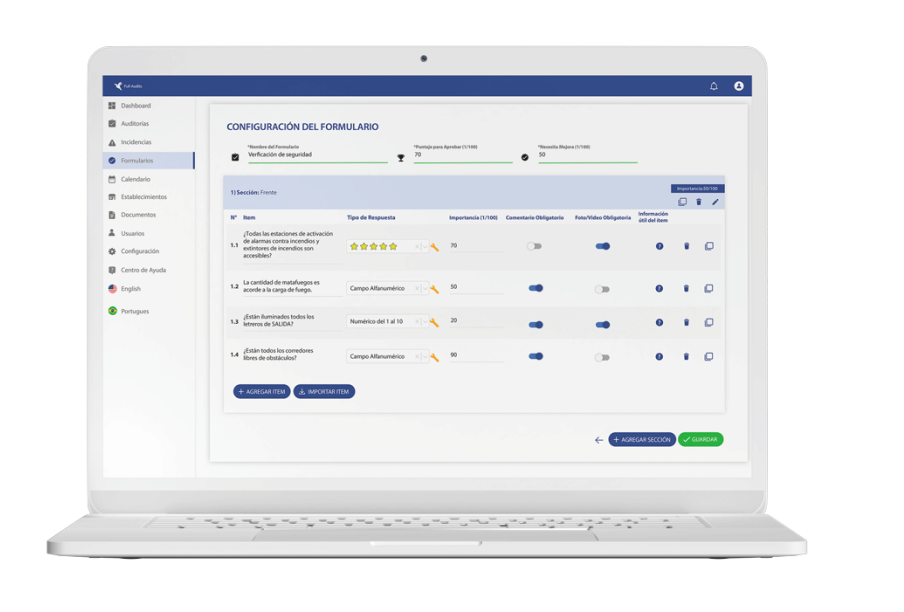

Implement checklists to improve your processes

Download the most popular checklists in your industry.